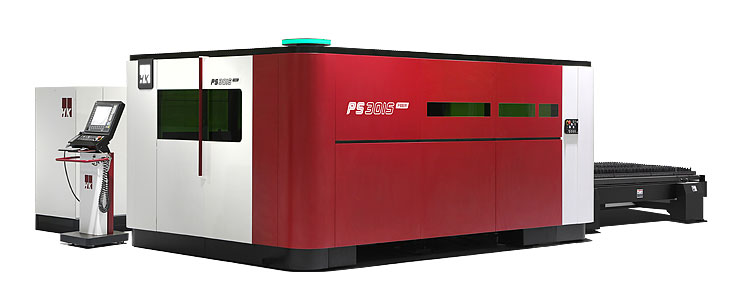

2022 best sheet metal laser cutter ST-FC3015C is the top rated full sheet metal cutting system for metal fabrication, which is suitable for custom and personalized metal signs, metal crafts, metal arts, metal logos, metal tags, metal letters, metal words. Now the best sheet metal laser cutting machine for sale at cost price.

A fiber laser cutter is an automated metal cutting system that uses a CNC controller to drive the 1064nm laser beam from a fiber laser generator to move along the tool path generated by the CAD/CAM software to achieve the metal fabrication plans. It is a fine precision cutting system for both sheet metals and tubes. It can cut both flat and beveled metal shapes and profiles. With a robotic arm, it can do 3D laser-cut jobs. It uses the non-contact cutting method of laser beam, which will not damage the substrate, and the thermal influence of the spot irradiation area is smaller. It can cut carbon steel, stainless steel, spring steel, silicon steel, aluminum, galvanized sheet, pickling sheet, gold, silver, titanium, copper, brass, and alloys. It is used for sheet metal fabrication, elevator manufacturing, electronic appliances, auto parts, machinery manufacturing, precision parts, marine aviation, metal crafts, and advertising.